How to Test Continuity Using a Digital Multimeter (Step-by-Step Guide)

- Kalyan Bhattacharjee

- Dec 21, 2025

- 4 min read

Updated: Jan 23

Let's Dive In | Continuity Testing Using Multimeter

If you’ve ever dealt with a device that suddenly stopped working no power, no response, no obvious damage, chances are the problem wasn’t complicated at all. In many cases, it’s simply a broken wire, loose connection, or faulty component hiding in plain sight.

This is where continuity testing using a digital multimeter (DMM) becomes one of the most valuable troubleshooting skills you can learn.

It’s simple, fast, and often the first test professionals perform before replacing parts or tearing down a circuit. Let’s walk through it properly - not just how to do it, but why it works and what most beginners get wrong.

What Is Continuity Testing?

Continuity testing checks whether electric current can flow uninterrupted between two points in a circuit.

In simple terms:

✔ Continuity present → Path is complete

✖ No continuity → Path is broken

A digital multimeter does this by sending a very small current through the circuit and checking if it returns. If it does, the meter confirms a complete path — often with a beep sound, which makes testing quick and intuitive.

When Should You Check Continuity?

Continuity testing is commonly used to:

Detect broken wires or cables

Test fuses and switches

Verify PCB traces

Check solder joints

Identify faulty connectors

Confirm ground connections

A lesser-known insight: Experienced technicians often check continuity before measuring voltage or resistance because there’s no point testing a circuit that isn’t even electrically connected.

What You Need

You only need two things:

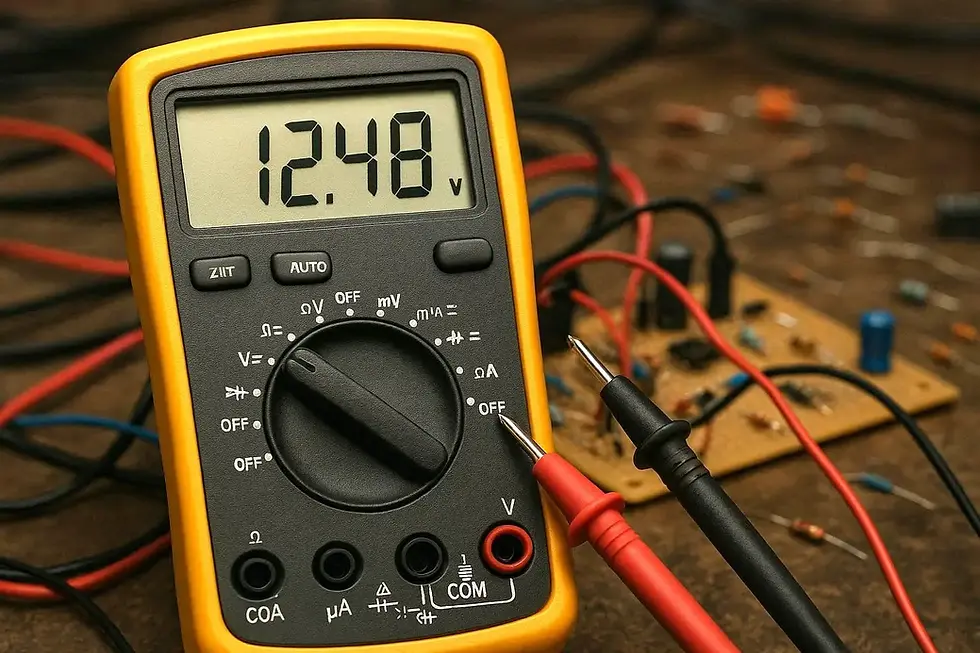

A digital multimeter with continuity mode

The circuit, wire, or component you want to test

Most modern multimeters even budget ones, include continuity testing.

Understanding the Continuity Symbol on a Multimeter

Continuity mode is usually marked by:

A sound wave or diode symbol

Sometimes combined with the resistance (Ω) setting

When continuity is detected, the Multimeter

It produces a beep or visual indicator, confirming that the circuit path is complete and electrically connected. So, it:

Emits a beep

Displays a very low resistance value (usually close to 0Ω)

No beep usually means an open circuit, broken connection, or faulty component that prevents current from flowing.

Important Safety Rule (Don’t Skip This)

👉 Always power OFF the circuit before checking continuity.

Testing continuity on a live circuit can:

Damage the multimeter

Give false readings

In worst cases, harm the user

This is one of the most common beginner mistakes.

Step-by-Step: Check Continuity Using a Digital Multimeter

Follow these simple steps to safely test whether an electrical path is complete using a digital multimeter.

Turn Off Power

Disconnect the device from power. Remove batteries or unplug it from mains electricity. This prevents electric shock and protects both you and the multimeter from damage.

Set the Multimeter to Continuity Mode

Rotate the dial to the continuity symbol. Some meters require pressing a “mode” button. A beep or symbol on the display confirms that continuity mode is active.

Test the Multimeter

Touch the two probes together.

✔ You should hear a beep

✔ The display should show near-zero resistance

If not, check the meter’s battery or probe connections.

Place the Probes on Test Points

Touch one probe to each end of:

A wire

A fuse

A PCB trace

A switch terminal

Probe polarity doesn’t matter for continuity testing.

Interpret the Result

Beep + low resistance → Continuity present

No beep / OL reading → Open circuit

That’s it - the result is immediate.

How to Test Common Components Using Continuity

This section shows how continuity mode can quickly identify breaks or faults in everyday electrical components.

Wires and Cables

Touch probes to both ends of the wire. No beep means the wire is broken internally. A continuous beep indicates the wire is intact and current can flow freely through it.

Fuses

A good fuse beeps. A blown fuse shows no continuity.

This test is far more reliable than visual inspection.

Switches

Test with the switch ON and OFF:

ON → Beep

OFF → No beep

If behavior doesn’t match, the switch is faulty.

PCB Traces

Used heavily in electronics repair. A missing beep often reveals cracked or burnt traces invisible to the eye. Continuity testing helps confirm whether current can flow properly through the trace without removing components from the board.

Continuity vs Resistance — What’s the Difference?

Many people confuse the two.

Continuity mode: Fast yes/no check

Resistance mode (Ω): Measures exact resistance value

Continuity mode is optimized for speed and audible feedback, which is why technicians prefer it during diagnostics.

Common Mistakes to Avoid

Testing a powered circuit

Forgetting to test the multimeter first

Touching probes with fingers (can affect readings)

Assuming “no beep” always means failure (some components need resistance mode instead)

Testing components still connected to complex circuits (parallel paths can mislead results)

Pro tip: For accurate results, isolate the component whenever possible.

Why Continuity Testing Matters in Real Repairs

Instead of replacing parts blindly, you can pinpoint the exact failure point in minutes. Continuity testing saves:

Time

Money

Guesswork

In professional repair environments, this simple test prevents unnecessary board replacements worth thousands.

Final Thoughts

Learning how to check continuity using a digital multimeter is one of those foundational skills that pays off endlessly - whether you're fixing gadgets, working with PCBs, or just diagnosing household electronics.

It’s quick, safe (when done correctly), and incredibly powerful for troubleshooting. Once you get comfortable with it, you’ll wonder how you ever diagnosed problems without it.

Author: Kalyan Bhattacharjee

Category: Tech Tutorials | Hardware

Expertise: Computer Systems Analyst & Technology Research Writer

Source: Information compiled from electronics manuals, measurement standards, and publicly available technical guides

Related Keywords: continuity using multimeter, how to test continuity using a multimeter, how to measure continuity using a multimeter, how to use multimeter to test continuity, how to continuity test using multimeter, how to continuity test using multimeter, how to check continuity using multimeter, multimeter continuity test, continuity setting on multimeter, check continuity with multimeter, continuity electric, continuity test symbol, multimeter continuity beep meaning, continuity test for wires, continuity test for PCB, fintech shield

Comments